A few good 3d printing fast prototyping photos I found:

3D Print Canal Residence

Image by waterboyzoo

3D Print Canal Home

Image by waterboyzoo

3D Print Canal Home

Image by waterboyzoo

3D Print China Company

A few good 3d printing fast prototyping photos I found:

3D Print Canal Residence

Image by waterboyzoo

3D Print Canal Home

Image by waterboyzoo

3D Print Canal Home

Image by waterboyzoo

Some cool 3d printing speedy prototyping photos:

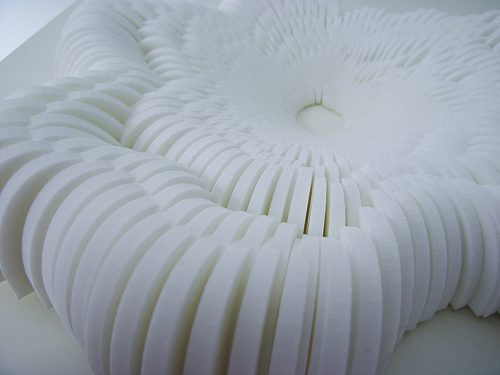

Frozen 085 Marius Watz: Sound memory (Oslo Rain Manifesto)

Image by watz

Marius Watz: Sound memory (Oslo Rain Manifesto). Speedy prototyping object primarily based on FFT information from the song "Oslo Rain Manifesto" by Alexander Rishaug.

3D Print Canal Residence

Image by waterboyzoo

3D Print Canal Home

Image by waterboyzoo

3D Hubs Assists Fast Prototype the Perfect Chef's Knife and Craft a Million …

The service is an perfect way to provide people the capacity to 3D print models that they downloaded from the world wide web or models that they created themselves. And for tiny startups and young firms, the ability to conveniently rapid prototype their …

Study a lot more on 3DPrint.com

A rapid prototyping service can speed up health-related device development

The Boston Young children's Hospital Simulator Plan, SIMPeds, has begun generating its 3D printing and engineering service obtainable to aid hospital employees rapidly prototype new devices. The aim is to get suggestions place into motion rapidly so that they can get to …

Read more on MedCity News

Some cool 3d printing speedy prototyping services images:

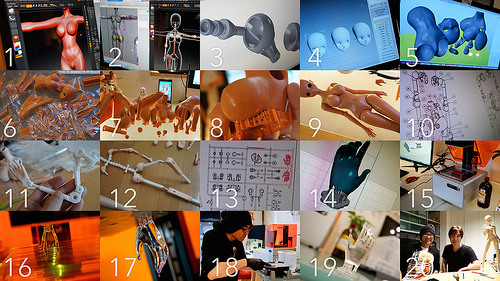

About Culture Japan

Image by Danny Choo

Intelligent Doll Production Jobs

Intelligent Doll production is done in Japan – body frames are injection molded in Yamagata and outer shell components casted in Katsushika Tokyo. Some apparel and wig products are made in Korea which has a wealthy BJD (Ball Jointed Doll) culture.

Sensible Doll production is thrilling because it’s our first time carrying out it. There is so much to understand, invent, construct and expand/increase upon.

The BJD is nevertheless a modest niche industry and it is our job to bring this kind of art and inspiration to the rest of the planet – and we have been undertaking so – about 80% of our clients are first time style doll owners.

Inventory, Purchase Order Management and Sales Forecasting

They might all sound boring but managing these 3 factors is key for any enterprise.

This job also includes managing relationships with vendors who generate components for us and anybody functioning on this group can expect 80% of their time to be devoted to keeping our good quality requirements.

Vendor’s are generally excellent at undertaking their specialist jobs but the level of quality is set by their clientele expectations – for this reason it is usually challenging in educating and changing the culture of vendors to function with our higher top quality needs.

Smart Doll Production

The Sensible Doll production group takes all the components and assembles everything with each other – but before this is accomplished, parts want to be rechecked (even after QA has gone by means of them, the flash requirements to be cut and a load of other processes want to be complete just before the body is prepared to be packed.

Apparel Development

Whilst there are a lot of doll seamstresses out there who can make high good quality apparel in tiny quantities, there are not numerous locations in the globe that are able to mass produce miniature garments at high high quality.

In order to speed up the concept > market place prepared approach, one particular of my ambitions is to improve headcount of our apparel group in Tokyo and setup apparel studios in different areas across Japan

Licensing

Wise Doll is the excellent platform for character license improvement for anime, games and Hollywood motion pictures also. In the quite close to future we strategy to start making Intelligent Doll’s of a variety of characters and will be needing people to manage not only the licensing agreements and supervision of prototypes at every stage by the licence holder, but also handle the production that will be involved in recreating the visual look and really feel of the character in miniature type.

Solution Development

Product development is also accomplished in our Tokyo offices. Collectively with our personal 3D modeling team and 3D printers, we rely heavily on 3D rapid prototyping strategies to get our goods to market place within short cycles.

Right after prototype creation, this team then has to perform out how and where the product is going to be mass produced, how it will be QC’ed, what the packaging will look like and how its produced etc.

This group is also responsible for things like making slush or injection molds, procuring elements and material, creating paint masks for the faceup (painting of the face), development of the eyes which includes thinking about ink saturation and how light is bent by means of the acrylic based on the eye radius and distance of print from eye surface etc.

Good quality Handle

80% of our time is taken up by Good quality Handle. All components that arrive in our workplace in Tokyo are checked and where feasible we try to fix something that can be carried out in residence – if not we send them back to the vendors and give them a spanking.

Fulfillment & Consumer Service

At the moment most of our orders are taken online employing Shopify and sometimes people come to the workplace to pick up. As we are nonetheless new to all of this, significantly of this approach is nonetheless very manual and includes printing picking lists, invoices, packing slips and so on.

Up until lately we employed shared email to handle buyer queries which was a nightmare but now we are employing Zendesk which enables us to collaboratively handle client queries and hold our sanity at the identical time.

Robotics

The Automated version of Smart Doll is now identified as Wise Doll Plus. Robotics development is a prohibitively expensive – we could easily spend all our cash flow on its production but fortunately have a lot more sense than money so we focus on the "Manual" version which is already on the marketplace and creating a self sustainable organization for us.

Obtaining stated that, I do invest resources working on this as a side project and will complete it.

3D Engineering

Our 3D Engineers are equipped with expertise to use a assortment of 3D application such as ZBrush, SolidWorks, Autocad, Rhinoceros, 3D Max, Maya and so on and are fully versed in problems relating to preparing the information for machining molds or for the printers we use in the office.

Our engineers have a very good understanding about the numerous sorts of manufacture and material properties which enables them to style although taking into account different factors such as injection molding slide, ejector pin, warpage, shrinkage concerns and so on.

View more at www.dannychoo.com/en/post/27288/About+Culture+Japan.html

Smart Doll

Image by Danny Choo

Design & Mold Preparation

1. The application we use to sculpt the physique is a 3D application package referred to as ZBrush.

2. ZBrush data is then imported into 3D Max for a variety of tweaks and to make confident every thing moves and fits collectively.

three. We used two various sorts of CAD packages for the frame – SolidWorks and Pro/ENGINEER.

four. The face is initially mirrored but then manually tweaked so that its not unnaturally symmetrical.

five. We use a computer software named Netfabb to prepare the information for printing.

six. Back then, I employed a 3D printing service in Tokyo called Digimode – all I needed to do was to submit my STL data and a couple of days later they would send back the parts.

7. Digimode used the Envisiontec Ultra speedy prototyping machine to print the parts.

eight. The bits that you see attached to the bottom of the bust are known as Assistance Structures which require to be snapped off and sanded down.

9. This is the initial time I see my creation as a complete ^o^ The subsequent step is discussed in the following section "Soft Vinyl Mold Preparation."

10. Now that the physique shell information is complete, we need to have to tweak the internal frame information based on findings from our 3D printouts.

11. We used a 3D printer that printed in nylon as it was the optimum material required to see how joints rubbed against and fitted with every single other.

12. We tweak the data based on the 3D printouts and repeat the process a zillion occasions till we feel the design and style is optimum.

13. The frame is going to be injection molded so we want to prepare the mold data. This method was way far more complex than I imagined and involved knowledge of material flow, cooling levels, wrinkling, warpage, mold temperature, injection stress and so forth etc – all that and more just to know exactly where to place the pieces in the mold and where to attach the runner gates.

14. Soon after a although, we managed to get our personal 3D printer which we began to use for production (assessment here). Just like before, we prepare some STL data of the component to be printed and load it into the printer software called PreForm.

15. Preparation of the printer by pouring in the clear resin.

16. An ultraviolet laser beams up from inside the printer and hits the bottom of the tank to cure the resin.

17. This hand can take between 2 and 6 hours based on the layer thickness setting.

18. The printed components are then removed from the Build Platform.

19. To use this printout for our doll production, I cut off the Assistance Structures and then sand down the surface to prepare it for the subsequent step which is Casting. My goal is to create a copper mold utilized for mass production of the soft vinyl shell.

20. Photo together with Miyata Noriaki who I developed the frame with.

View far more at www.dannychoo.com/en/post/27195/Smart+Doll.html

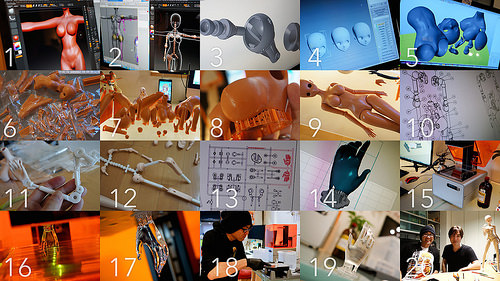

The Producing of Smart Doll

Image by Danny Choo

Design and style & Mold Preparation

The computer software we use to sculpt the physique is a 3D computer software package referred to as ZBrush.

ZBrush information is then imported into 3D Max for various tweaks and to make confident everything moves and fits with each other.

We employed two various kinds of CAD packages for the frame – SolidWorks and Pro/ENGINEER.

The face is initially mirrored but then manually tweaked so that its not unnaturally symmetrical.

We use a application called Netfabb to prepare the information for printing.

Back then, I employed a 3D printing service in Tokyo referred to as Digimode – all I required to do was to submit my STL information and a few days later they would send back the components.

Digimode employed the Envisiontec Ultra fast prototyping machine to print the parts.

The bits that you see attached to the bottom of the bust are called Help Structures which require to be snapped off and sanded down.

This is the very first time I see my creation as a entire ^o^ The next step is discussed in the following section "Soft Vinyl Mold Preparation."

Now that the body shell data is full, we require to tweak the internal frame data primarily based on findings from our 3D printouts.

We employed a 3D printer that printed in nylon as it was the optimum material necessary to see how joints rubbed against and fitted with each and every other.

We tweak the data based on the 3D printouts and repeat the approach a zillion occasions till we really feel the design is optimum.

The frame is going to be injection molded so we want to prepare the mold data. This method was way more complex than I imagined and involved knowledge of material flow, cooling levels, wrinkling, warpage, mold temperature, injection stress etc and so on – all that and much more just to know where to put the pieces in the mold and where to attach the runner gates.

Right after a even though, we managed to get our personal 3D printer which we began to use for production (overview here). Just like prior to, we prepare some STL information of the part to be printed and load it into the printer software program referred to as PreForm.

Preparation of the printer by pouring in the clear resin.

An ultraviolet laser beams up from inside the printer and hits the bottom of the tank to cure the resin.

This hand can take amongst 2 and 6 hours depending on the layer thickness setting.

The printed parts are then removed from the Construct Platform.

To use this printout for our doll production, I reduce off the Assistance Structures and then sand down the surface to prepare it for the subsequent step which is Casting. My aim is to develop a copper mold utilised for mass production of the soft vinyl shell.

Photo with each other with Miyata Noriaki who I developed the frame with.

View more at www.dannychoo.com/en/post/27275/The+Producing+of+Intelligent+Doll….