A few nice low-cost 3d printing service pictures I found:

MakerBay in South China Morning Post cover

Image by cesarharada.com

Credits Christine Yeh

www.scmp.com/way of life/write-up/1901185/hong-kongs-makerba…

Cesar Harada , founder of MakerBay, with "Protei", a revolutionary shape-shifting sailing robot used to explore and shield the ocean with Open Source Technologies.

It took inventors Cesar Harada and Shawn Frayne just a couple of days to produce their most recent item – an inexpensive children’s constructing toy consisting of colourful plastic rods with magnetised ends.

Both men’s core expertise lies elsewhere: Harada styles versatile robotic boats that can be utilized on environmental missions Frayne launched a micro-wind device company and went on to run Looking Glass, a begin-up making 3D displays.

Their collaboration came about simply because both are part of MakerBay, the shared production space Harada set up a little a lot more than a year ago in Yau Tong, exactly where hobbyists and inventors alike can gather to tinker, develop, invent – and understand from every other.

Cesar Harada, founder of MakerBay in Yau Tong. Photo: David Wong

Cesar Harada, founder of MakerBay in Yau Tong. Photo: David Wong

“The thought is a space like this where collaboration happens organically and we can invent some thing speedily. [Generating anything] does not have to be a extremely extended journey. If you are in the proper spot, with the appropriate individuals and a lot of tools, and you create a network that supports these people, then the journey can be significantly faster,” Harada says.

Becoming a maker changes the perception of the planet. You don’t really feel limited. You feel that the world can be changedCESAR HARADA

“We wanted to make a toy for kids with no money, without having space, and one that we can make quite quickly. And so we created a drawing, discovered some straws in the kitchen and some magnets in the office and we place them together. We ordered far more components from Taobao next day and in 48 hours we had the prototype.”

The maker movement, which former Wired magazine editor Chris Anderson described as “the internet generation creating physical things rather than just pixels on screens”, is a nascent 1 in Hong Kong.

Dim Sum Labs in Sheung Wan, the initial hacker space in the city, has been joined only by MakerHive, a little co-functioning space in Kennedy Town, and Harada’s MakerBay, which occupies a 6,500 sq ft space in an industrial building and gives tools from screwdrivers and soldering irons to laser cutters and 3D printers.

Tools at MakerBay positioned in an industrial creating in Yau Tong. Photo: David Wong

Tools at MakerBay located in an industrial constructing in Yau Tong. Photo: David Wong

But they bring together diverse talents. MakerBay has attracted hobbyists such as Andrew Pearce, a frequent traveller utilizing his stay in Hong Kong to generate his dream surfboard, as nicely as organizations such as Frayne’s Seeking Glass.

British ecologist and MakerBay member Andrew Pearce in the MakerBay workshop. Photo: David Wong

British ecologist and MakerBay member Andrew Pearce in the MakerBay workshop. Photo: David Wong

Originally primarily based in Kwun Tong, the organization moved to MakerBay shortly soon after it opened.

Alvin Lee Shiu-pong, an engineer at Searching Glass, says he and his colleagues uncover the co-operating platform a excellent location for building new merchandise.

“We can meet a lot of like-minded men and women and share our tips. The workshop is truly practical. Obtaining our personal tool lab would call for a big investment it’s significantly less expensive if we can share the tools.”

Lee says the “volumetric” displays they specialise in would be beneficial for the medical globe and beyond.

“Instead of dissecting bodies or searching at 2D photos from books, students can use a volumetric display to discover about human bodies,” he says, gesturing towards a transparent brick inked with a detailed 3D display of the structures inside a skull.

“All we want is to method the 3D data we’ve obtained [to kind the display] and assign colours according to the diverse densities identified – a higher density would indicate bone and reduced ones can be blood, flesh or tendon,” he explains.

The same approach could be applied to learn about the structures of insects or even micro-organisms, adds Lee, whose group is refining the subsequent massive issue from Hunting Glass – a cube which can show LED sequences based on code that a user has written.

British ecologistPearce shares his enthusiasm for the hacker space. Tired of paying hefty airline charges to ship his surfboards and of getting boards that don’t meet his preferences, he decided to make his personal. He has been creating excellent use of the tools at MakerBay and picking up skills at its workshops to experiment with distinct materials and methods of making surfboards.

“It’s just a good way of learning factors,” says Pearce. “It’s the very first time I tried to make some thing. Right here, I’ve figured out how to make designs in 3D and make them with the laser cutter. I’ve completed an induction workshop on woodworking, as well. And if I managed somehow to get this new approach of constructing down then I guess it can be a saleable concept.

“I do have a mini Simmons [surfboard] but I can not take it with me since of all the charges for the airline. You have got this limit on the MTR as well, which is even smaller – you can not even take one thing as higher as yourself. That’s why I have to design some thing that slots with each other, which is difficult.”

L3D Cube.

L3D Cube.

Pearce may have picked up a few ideas at the Maker Faire Hong Kong in November, when veteran model maker Chung King-yang showed a foldable canoe produced from plastic foam and epoxy resin.

The two-day event, which drew entries from far more than 300 individual makers and schools, was organised by Dr Choy Sze-tsan.

An assistant professor in the college of design and style at Polytechnic University, Choy previously sponsored a mini event run by the Hong Kong Makers’ Club. But soon after 3 years, he decided it was time to turn the faire into a bigger event and involve a lot more schools.

Harada presented his building toy at the occasion and the optimistic feedback has encouraged him to place it on the marketplace soon. As may be expected, Dim Sum Labs was also present and ran soldering workshops.

Hong Kong traditionally is more service- and finance-oriented. Folks here are less about generating issues. They’re a lot more about transactionsJASON HSU

Visitors got the likelihood to test-drive underwater robots produced by German Swiss International College, get their hands on diverse maker things and, more importantly, be inspired.

Whilst conventional fairs tend to be locations to sell things, Maker Faires are all about nurturing creativity and sharing of expertise, Choy says.

At its heart, design covers the broader intention to identify issues and come up with solutions to improve our world, which has a lot to do with the maker culture, he adds it is not simply about enhancing aesthetics.

So despite the fact that some people might take into account items featured at the show to be useless stuff, the concepts might be the genesis of something far larger.

“A effective invention comes not overnight, but right after tonnes of experimentations. At the Maker Faire, men and women can see so many distinct possibilities of solving troubles creatively, it’s not possible for them not to get inspired,” Choy says.

“The maker culture is a excellent catalyst for men and women to reconnect back to our physical planet and discover through failures and trial and error. Via creating and the uncertainties that arise from the method, we venture into the unknown. And if there’re glitches, it is OK since they hold us trying even tougher.”

Harada agrees: “Everyone in their heart has the need to do something exciting with their life and if you only perform on a pc, there’re some limitations. But as soon as you start to make some thing, you can develop an object or adjust the environment.

“Being a maker changes the perception of the globe. You don’t really feel restricted. You feel that the globe can be changed and that is true for every little thing from objects to buildings to politics.”

Some enthusiasts view the maker movement as holding the seeds to a third industrial revolution. Jason Hsu Yu-jen, founder of Taiwan’s MakerBar, goes so far as to say that our future could lie in the maker culture.Navigating a power drill kart made by Wheel Issue Makers.

Navigating a power drill kart made by Wheel Thing Makers.

“MakerBar is much more than just a co-working space. It has evolved to turn out to be a international platform,” says Hsu, who was in Hong Kong last month to speak at a symposium organised by the Hong Kong Federation of Design and style Associations.

“Most individuals feel about makers as a enterprise model. That’s wrong. The maker culture is not just about [employing] 3D printing or laser cutters. [Getting a] maker is a mindset. It is a way to resolve issues creatively.

“What you see as the maker movement nowadays is what world wide web or software was back in the early ’80s when Steve Jobs 1st launched the Macintosh private computer systems. In the future, because of de-monetisation and democratisation of technologies, the expense for technology would be practically free of charge and you need to use your service to make cash, not with the machine.

“The maker culture is important for its social engineering effect. It could be a new tool to change society, specifically in the creating planet. In the countryside or farm communities in remote China, makers could be utilised as a hub to change villagers’ life. It will modify villagers’ life the way e-commerce will alter China. That’s my vision.”

Jason Hsu, of MakerBar Taipei. Photo: Jonathan Wong

Jason Hsu, of MakerBar Taipei. Photo: Jonathan Wong

Even so, compared to the mushrooming maker spaces in Taiwan and Shenzhen, the movement in Hong Kong clearly has a long way to go.

This lag is because “Hong Kong traditionally is more service- and finance-oriented. People right here are less about generating issues. They’re much more about transactions,” Hsu says.

The perception of producing as a non-profit activity is surely a issue in Hongkongers’ lack of involvement, Choy concedes. “But in reality, besides cultural and intellectual elements, there can be economic worth,” he says. “Take Japan’s Maywa Denki, for instance. Their quirky musical inventions which they execute common shows with are their supply of revenue.”

MakerBay’s Harada says another purpose why the maker culture has been so slow to create in the city is simply because “the mentality of Hong Kong has been educated as well much towards competitors and not towards collaboration”.

“They have been attempting a lot more to take benefit of every other as an alternative of helping each other. This has to change,” he says.

“In Silicon Valley this culture of maker space, sharing and exceptional innovation has been about for 15 years and this is why Silicon Valley is Silicon Valley. People young and old have to open their minds, be prepared to experiment and share the sources as an alternative of keeping factors to themselves.”

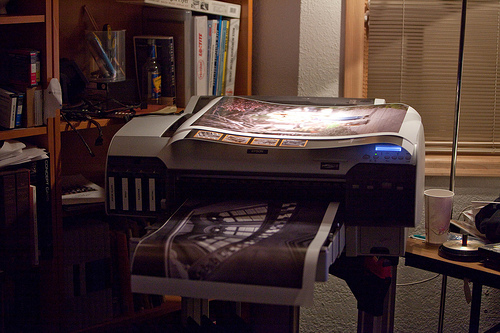

TwingeeksPhoto’s newest capability addition – 17″ roll kind paper printing.

Image by ttstam

Scored an Epson 4000 off Craigslist – 17′ wide roll form paper that operates on Epson UltraChrome ink. Original MSRP of this bad boy is about 00-00, guy was asking for it. I had him do a nozzle check, which showed that due to storage, the ink had clogged up the lines. desparate to sell he supplied it to me @ .

i figured… if I can fix a 3D printer, 2D printer should not be a issue. So armed with a service manaula i identified on the web and some solvent and cleaning supplies, over the final 6 months I disassembled and carefully reassembled the head subassembly and flushed out the ink lines. It is now printing nicely (I am using a low cost generic knockoff inkset for testing and what ever proofing paper came with the printer. becoming in a position to print 16" tall, up to 100ft wide panoramas, or being able to do 16"x20s and 16" x 24s in residence even though, is a true good bonus.

Next step is to save up my pennies for a good continous inking technique and colour calibrate the output against the brand name fine art papers.